Our partner can provide the inertia friction welding.

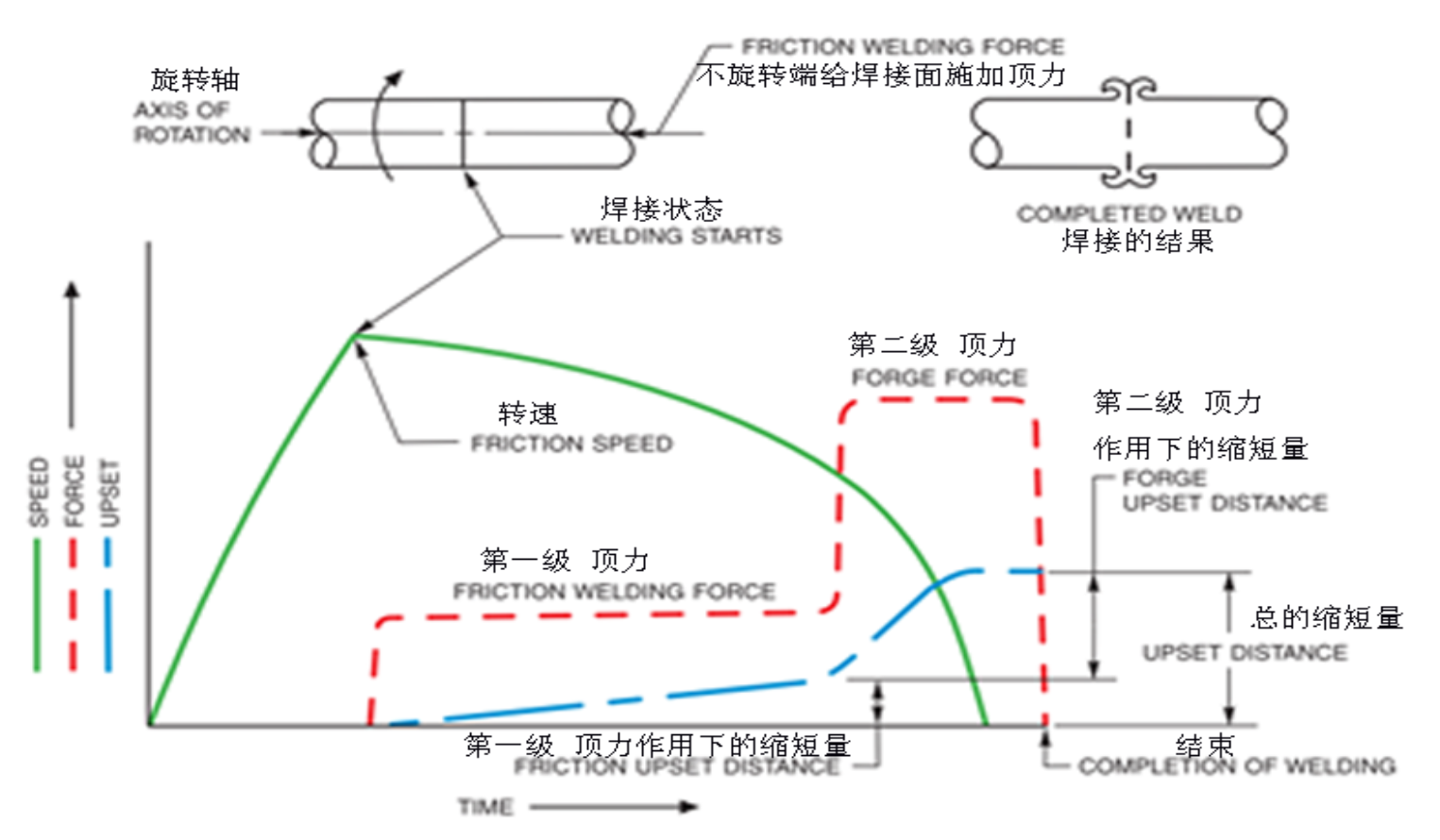

Chart: Typical process of inertia friction welding

Friction welding has many advantages than the traditional welding methods:

1. High-quality solid phase welding joints, no phase change, no solidification defects, and the strength is equivalent to the material itself.

2.comprehensive material welding, the application covers all commonly used industrial metal materials, regardless of the welding of almost the same or dissimilar materials.

Aluminum welded with Steel

3.Extremely high production efficiency, we can complete the welding of a solid steel rod with a diameter of 180mm in 80 seconds for the whole process : acceleration, welding and pressure maintaining process.

If you have the request for welding two kind of metal material, you can try with ORK, we will find solution for you .

Tungsten welded with Copper